Businesses are growing rapidly. To win the competition there is a great need to be creative and responsive to new problems. Customers have many options for a single product. To sustain in the market you need to be very innovative in your business design. For example, you should adopt modern manufacturing techniques. The steps involved in making a new product are, idea generation, screening, testing, prototyping, and manufacturing.

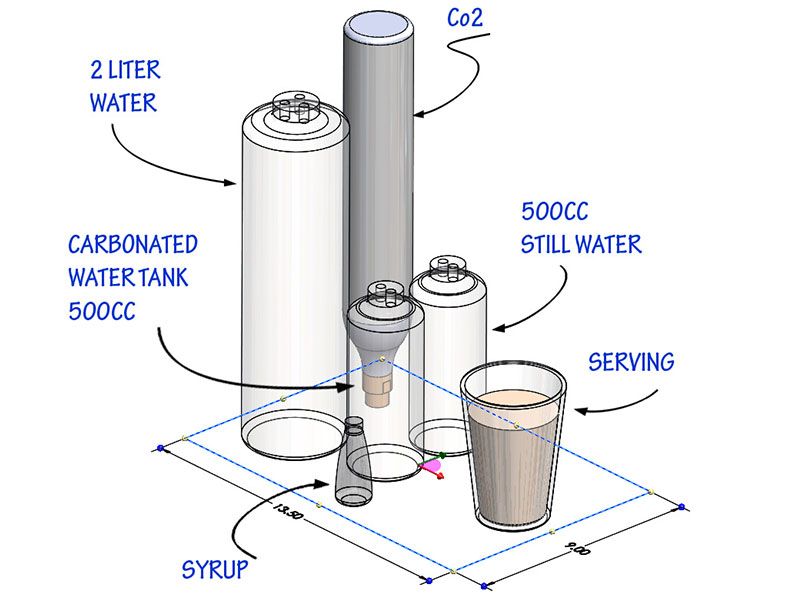

In all the above-mentioned steps, the most important one is prototyping. It is a technique that works to get amazing end products. As it creates a visual image to give an idea about the actual product. This is the first step in the manufacturing of a product. Companies hire product designers for this purpose. Rapid prototyping engineers can also serve the same. This pre-design of a product will be used to test the actual working of the product before its production. It will be a costly process. To make a prototype for a product needs funds and ample resources. As professional services are involved in all this process. They help you to visualize the product in 3D and 4D models.

Rapid prototyping is a very beneficial technology to use. You can get the following benefits from it.

Table of Contents

Flaws correction:

There were times when industries used to make 2D sketches for their products. They were unable to identify the flaw in the design as it was on paper. But now product designers can make a 3D design that gives the client a clear picture of their desired design. They can identify flaws before manufacturing the product and can correct them. Prototyping makes the innovation easy and adoptive. Industries can get most of the benefits from this technology to get a flawless end product.

A clear idea of the product:

Prototyping gives industrialists and designers a chance to see how their actual product will work. They can visualize it, modify it according to the needs and requirements. Huge resources are sometimes require to make a prototype of an industrial product but it can save you from loss as well. Companies can work on their product and can add new features.

Perfect product:

To have a perfect product at the end, it is necessary to make some prototype drawings and designs. This will help a designer to rectify those faults according to the demand of the customer. Some prototypes allow the companies to check the functionality of the design. Will it be suitable or not? Having a faulty product that doesn’t match your idea can be frustrating. To save from inconvenience, prototyping is a good idea.

Efficient approach:

Companies don’t need to take a test product to check will it work or not. They simply need a product designer or rapid prototyping engineer with CAD software and an idea. The 3D design will take less time and save your cost drastically. Prototyping is a very efficient approach to have a competitive advantage over others as well. It can speed up your innovative production.

Saves time:

When companies are involved in new product development. It can take a lot of time to test your product and then identify faults and rectify them. But if you have your idea in the 3D form, you can make changes in time and mold it according to the customer demand. This technology has saved plenty of time for industrialists.

Cost reduction:

Prototyping has cut costs drastically. It allows companies to correct, modify the product before manufacturing. The entire project cost can be reduced by using this art of 3D designs. Let suppose a defense industry has to plant machinery. The cost of machinery is 50000 dollars. Is it possible for designers to make a testing product for it? The answer is No, there is a great risk involved in the manufacturing of a test product on a huge budget.

Evaluation of product:

Prototyping allows designers to evaluate their product before finalizing the design. It allows checking the functionality of the product. Companies can use this prototype for customer review and can have suggestions from the users. Most companies design prototypes for their new product and arrange an exhibition for that. They allow their customers to test them and give feedback. This is a very useful way to have a quality product.

There are many types of prototyping like high and low-fidelity. Companies can opt for the type according to their needs. Rapid prototyping is a cost-effective technique. If the company plays all its cards right for prototyping. They can get the desired results. Prototyping goes wrong and is a waste of time sometimes if you lack resources. You must consider product designers or professionals for this process if you want to have all the above benefits for your business.

Many companies also offer their services for rapid prototyping only. Industrialists can outsource the process of prototyping to get maximum output.